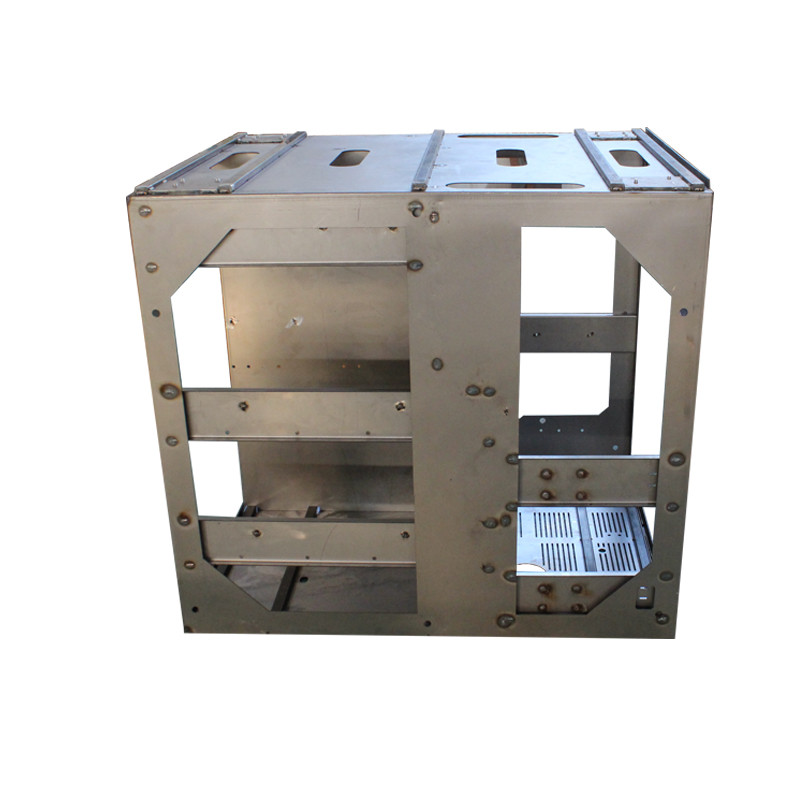

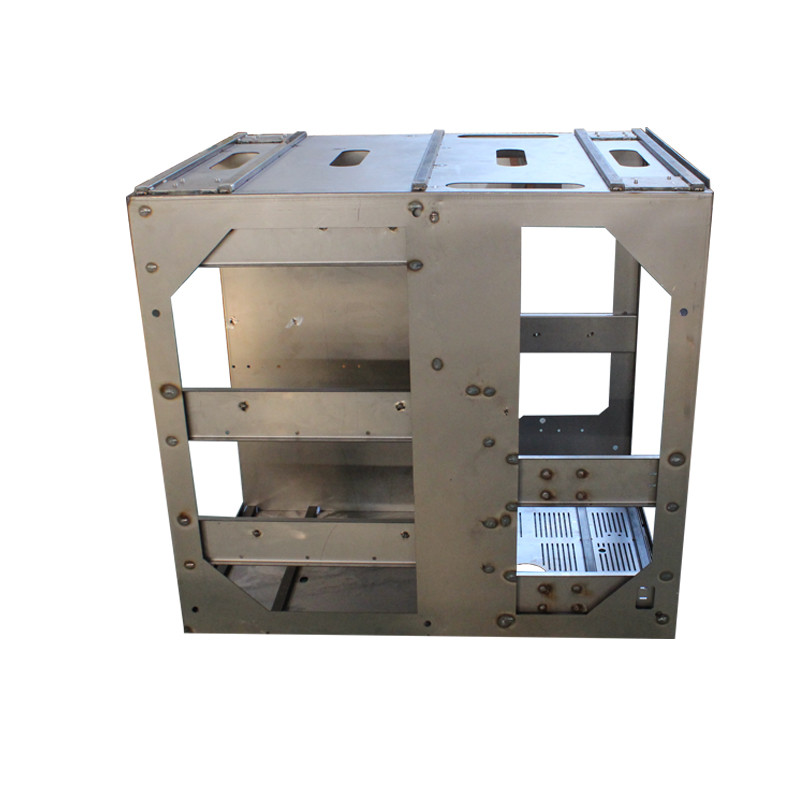

Inkonzo yokuwelda iStainless Steel Parts ngokweSiko

Ingcaciso yeMveliso

Ukumelana ne-welding

Ukuchaswa kwe-welding yindlela ye-welding apho i-workpiece idibaniswe kwaye uxinzelelo lusetyenziswa nge-electrode, kwaye umbane wombane usetyenziswa ngobushushu obuchasayo obuveliswa ngummandla woqhagamshelwano kunye nommandla okufutshane wokudibanisa.I-Resistance welding yindlela yokufudumeza i-workpiece kwisimo esityhidiweyo okanye seplastiki ngumbane wombane ojikelezayo kwindawo yokudibanisa kunye neendawo ezikufutshane.Kukho iindlela ezine eziphambili zokumelana nokuwelda, ezizezi, ukuwelda kwebala, ukuwelda komthungo, ukuwelda kwentelekelelo kunye ne-butt welding.

Ukuwelda kwekharbhon diokside

Igesi ekhuselayo ye-carbon dioxide arc welding yi-carbon dioxide (ngamanye amaxesha umxube we-CO2 + Ar).Isetyenziswa kakhulu kwi-welding manual.Ngenxa yempembelelo ekhethekileyo yezinto eziphathekayo ze-thermal zegesi ye-carbon dioxide, xa usebenzisa umbane we-welding yesiqhelo, akunakwenzeka ukwenza i-axial elungeleleneyo yenguqu yamahhala ngokunyibilikisa isinyithi ekupheleni kocingo lwe-welding, edla ngokufuna isiphaluka esifutshane kunye ne-droplet necking. ugqabhuko-dubulo.Ke ngoko, xa kuthelekiswa ne-MIG welding yenguqu yasimahla, kukho ukuchaphaza okungakumbi.Kodwa ukuba ukusetyenziswa komgangatho ophezulu we-welding machine, ukhetho olufanelekileyo lweeparameters, lunokufumana inkqubo ye-welding ezinzileyo kakhulu, ukwenzela ukuba i-spatter iyancipha ukuya kwinqanaba elincinci.Ngenxa yeendleko eziphantsi zegesi ekhuselayo esetyenzisiweyo, i-weld yenziwe kakuhle xa usebenzisa i-short circuit transition, idibene nokusetyenziswa kocingo oluqukethe i-deoxidizer inokufumaneka ngaphandle kweziphene zangaphakathi zokudibanisa umgangatho we-welding.Ke ngoko, le ndlela yokuwelda iye yaba yenye yezona ndlela zibalulekileyo zokudibanisa izinto zentsimbi.

Argon arc welding

I-Argon arc welding yiteknoloji ye-welding esebenzisa i-argon gas njengegesi ekhuselayo.Ikwabizwa ngokuba yi-argon body protection welding.Kukudlula i-argon igesi ekhuselayo ejikeleze i-arc welding ukuze ihlukanise umoya ngaphandle kwendawo ye-welding kunye nokukhusela i-oxidation yendawo ye-welding.

Itekhnoloji yokuwelda iArgon isekelwe kumgaqo wokuwelda ombane oqhelekileyo we-arc, usebenzisa ukhuseleko lwerhasi ye-argon yezixhobo zokuwelda isinyithi, ngokuphezulu kwangoku kwi-welding backing material weld iyanyibilika ibe yi-liquid pool formation, ibangele i-weld metal kunye ne-weld material. i-metallurgy idityaniswe nohlobo lwetekhnoloji ye-welding, kubushushu obuphezulu obunyibilika ukuwelda kwi-argon rhoqo, yenza izinto ze-weld zingakwazi ukunxibelelana neoksijini emoyeni, Ngaloo ndlela ukuthintela i-oxidation ye-welding material, ukuze ukwazi ukuwelda insimbi engenasici, isinyithi sentsimbi.

Ukuwelda kweLaser

Ukuwelda kweLaser kunokuqondwa ngokuqhubekayo okanye nge-pulsed laser beam.Umgaqo we-laser welding unokwahlulwa ube yi-welding conduction welding kunye ne-laser ye-fusion deep welding.Xa uxinano lwamandla lungaphantsi kwe-10-10 W / cm, kukufudumeza ukufudumala kwe-welding, kunye nobunzulu be-welding kunye nesantya se-welding siyacotha.Xa uxinano lwamandla lungaphezu kwe-10 ~ 10 W / cm, umphezulu wesinyithi ugobekile ube "yimingxuma" phantsi kwesenzo sobushushu, senza i-welding ye-fusion enzulu, eneempawu zesantya sokudibanisa ngokukhawuleza kunye nomlinganiselo omkhulu wobunzulu ukuya kububanzi.

Umgaqo we-laser conduction welding welding kukuba: i-laser radiation ifudumeza umphezulu ukuba iqhutywe, kwaye ubushushu bomhlaba busasazeka ngaphakathi ngokuqhuba ubushushu.Ngokulawula iiparamitha ze-laser ezinje ngobubanzi, amandla, amandla encopho kunye nokuphindaphinda okuphindaphindiweyo kwe-laser pulse, i-workpiece iyanyibilika kwaye ichibi elithile elityhidiweyo lenziwe.

Lambert sheet metal izisombululo isiko umboneleli izisombululo.

Ngeminyaka elishumi yamava kurhwebo lwangaphandle, sisebenza ngokukhethekileyo kumacandelo okulungisa intsimbi echanekileyo, ukusika i-laser, ukugoba kwentsimbi, izibiyeli zentsimbi, amaqokobhe entsimbi ye-chassis, izindlu zombane we-chassis, njl. , ukupolisha, ukuqhunyiswa kwesanti, ukutshiza, ukubethelwa, okungasetyenziswa kuyilo lwezorhwebo, amazibuko, iibhulorho, iziseko ezingundoqo, izakhiwo, iihotele, iinkqubo ezahlukeneyo zokubhobhoza, njl. umgangatho kunye neenkonzo ezisebenzayo zokusetyenzwa kubathengi bethu.Siyakwazi ukuvelisa amacandelo entsimbi yeemilo ezahlukeneyo ukuhlangabezana neemfuno zomatshini ezipheleleyo zabathengi.Sihlala sivelisa izinto ezintsha kwaye siphucula iinkqubo zethu zokuqinisekisa umgangatho kunye nokuhanjiswa, kwaye sihlala "sijolise kubathengi" ukubonelela abathengi bethu ngenkonzo esemgangathweni kwaye sibancede baphumelele impumelelo.Sijonge phambili ekwakheni ubudlelwane bexesha elide kunye nabathengi bethu kuzo zonke iindawo!