Ukusetyenzwa ngokwezifiso kunye neenzuzo zethu

I-Zhongshan Lambert Precision Hardware Co., Ltd. yifektri yorhwebo yangaphandle esebenza ngokukhethekileyo ekuqhubekeni phambili.Sinikezela nge-OEM, i-ODM kunye neenkonzo zokulungisa isiko.Iimveliso zethu zikumgangatho ophezulu kunye nexabiso elikhuphisanayo.Abathengi bethu abaphambili bavela kwiimarike eziphakathi kunye neziphezulu eYurophu, e-Australia naseMelika.

Inkampani yethu yasekwa ngo-2012.Siye saba ngabayili abanamava kunye namagcisa, kunye nabasebenzi abanobuchule bokuvelisa.Sinezixhobo zokusebenza eziphambili, kwaye ukuchaneka kwethu kufikelela kwi-± 0.02mm.Sineemfuno ezingqongqo kakhulu kumphezulu weemveliso zethu.Iimveliso zethu zinconywa kakhulu ngabathengi ngobungakanani bazo obuchanekileyo kunye nonyango olugqibeleleyo lomphezulu lujongeka njengemisebenzi yobugcisa.

Sinezi zixhobo zokusebenza eziphambili zilandelayo.

I-Laser yokusika ipleyiti yensimbi

Umatshini wokusika i-laser ye-sheet metal ngumatshini wokusika ochanekileyo ophezulu obanzi

esetyenziswa kushishino lwesinyithi.Isebenzisa umqadi we-laser ukusika izinto zetsimbi kwaye ine

iingenelo zokuchaneka okuphezulu, ukusika isantya esiphezulu, ukuguquguquka, ukusika ngaphandle koqhagamshelwano

kunye nolawulo oluzenzekelayo, luyenza ibe sisixhobo esiyimfuneko kule mihla

ishishini lesinyithi

Ukusika umbhobho we-3D

Aba matshini banokusika iityhubhu ezahlukeneyo ezingqukuva, zesikwere, ezisicaba kunye nezingaqhelekanga ngokuchanekileyo:

- - Umbhobho wentsimbi

- - Umbhobho wegalvanized

- - AISI 430 ityhubhu

- - AISI 304 ityhubhu

- INGCINGA:0.2mm - 50mm

- UBUKHULU ABANGAMNYE:φ220mm*6000 mm

- UNYAMEZELO:±0.05mm

Oomatshini bokugoba beshiti

Umatshini wokugoba weshiti luhlobo loomatshini kunye nezixhobo ngokukodwa

eyenzelwe ukusetyenzwa kwezixhobo zentsimbi.Umatshini wokugoba weshiti

ineengenelo zokusebenza okuphezulu, ukuchaneka okuphezulu, ukuguquguquka, ukusindisa umntu

izixhobo kunye nokuphucula umgangatho wemveliso.Inoluhlu olubanzi lwezicelo

kwaye inokuhlangabezana neemfuno zamashishini ahlukeneyo kunye nemimandla yokusetyenzwa kwesinyithi

Ukuwelda kwerobhothi

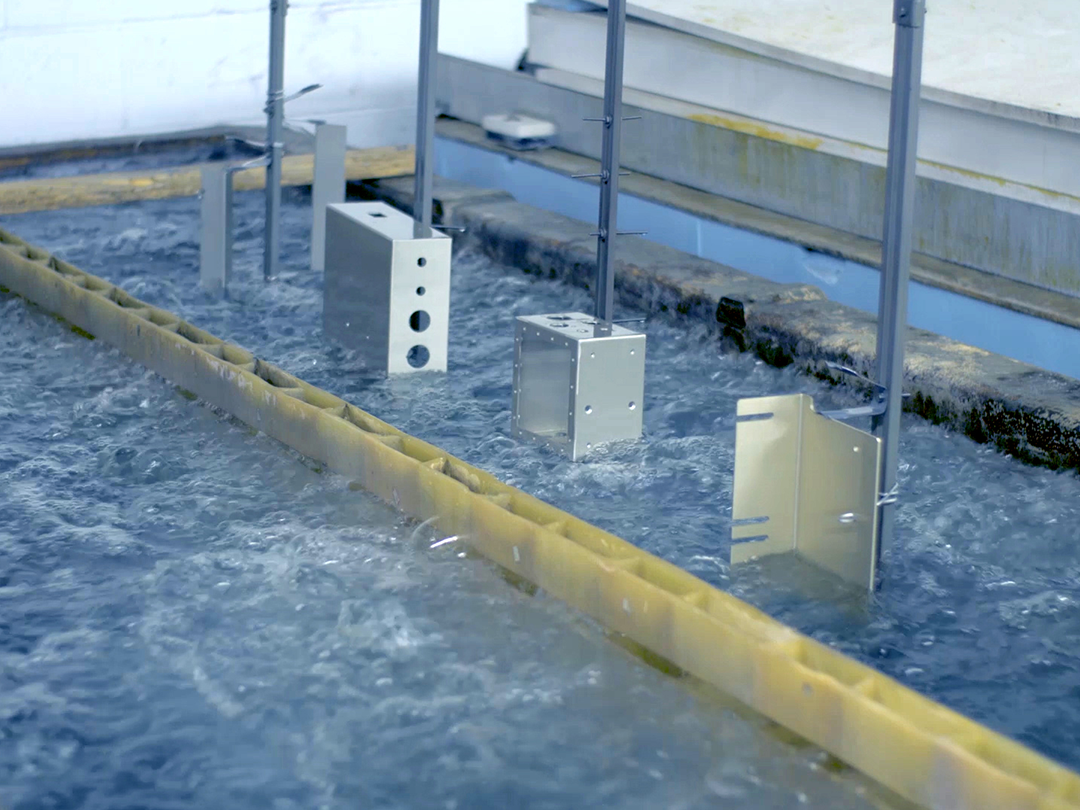

I-TIG yerobhothi(Tungsten Inert Gas) iziko welding.I-MIG yerobhothi(Metal-arc Inert Gas) iziko welding.Xa kudityaniswe nezinto ezikhethekileyo ezahlukeneyo, siyakwazi ukucubungula iindawo ezahlukeneyo ezintsonkothileyo.Sinokusebenzisa itekhnoloji ye-welding ezenzekelayo ngaphakathi kwebhokisi

Oomatshini bokusika beLaser becwecwe lesinyithi

Ngesantya esiphezulu, ukuchaneka okuphezulu, ukuguquguquka okuphezulu, i-burr ephantsi kunyeimveliso eliphezulu, sheet metal laser oomatshini ukusika ngokubanziisetyenziswe kwibala lokucwangcisa isinyithi ukuze kuphuculwe ukusetyenzwaukusebenza kakuhle kunye nomgangatho wemveliso

I-Laser tube cutter

Ishidi lentsimbi ye-laser tube cutter ngumatshini osebenzayo kwaye ochanekileyo owenzelweukusika iityhubhu zetsimbi.Ibonisa ukusika ngesantya esiphezulu, ukuchaneka okuphezulu kunye nokuguquguquka,eyenza ukugqitywa ngokukhawuleza komsebenzi wokusika kunye nokuqinisekisa umgangatho kunyeukuchaneka komphezulu osikiweyo

Uyilo lomzobo we-3D

Ngemizobo yoyilo lwe-3D, abavelisi banokujonga ukufaneleka kunye nokuveliswa kwemveliso yabo kwangaphambili, balungise izisombululo zoyilo, ukunciphisa iindleko zokuvelisa kunye nokuqinisekisa umgangatho kunye nokuchaneka kwemveliso yokugqibela.

Singabonelela ngeendlela ezahlukeneyo zonyango ezikumgangatho ophezulu.Umzekelo: ukugaya, ukupolisha, ukuzoba ucingo, i-electroplating, umgubo wokutshiza, i-anodizing, njl.

I-Sheet metal welding yinkqubo apho ii-workpieces zentsimbi ezimbini okanye ngaphezulu zidityaniswe bubushushu okanye uxinzelelo.Isetyenziselwa ukudibanisa amaphepha abhityileyo esinyithi kwaye isetyenziswa ngokuqhelekileyo ekwenzeni izakhiwo zetsimbi, amacandelo kunye nezikhongozeli njl.

Ukupholisha: Ukusila kunye nokupolishwa komphezulu weshiti kusetyenziswa izixhobo ezirhabaxa kunye neziqhoboshi ukwenza umphezulu ube mtyibilizi, ube mcaba kwaye ubengezele.

Uqhushumbisi lwesanti: I-sandblaster yoxinzelelo oluphezulu isetyenziselwa ukuqhushumba intlabathi kwiphepha lesinyithi umphezulu ukususa i-oxidation yomphezulu, amabala kunye nemibhobho ngokusebenzisa i-abrasion kunye nefuthe, ukwenza umphezulu ube mtyibilizi kwaye ufane.

Ukutshiza: Ukusebenzisa umpu wokutshiza, ipeyinti isetyenziswe kumphezulu wemveliso yentsimbi yokukhusela kunye nobuhle.Ukutshiza kungenziwa ngeentlobo ezahlukeneyo zepeyinti ezifana ne-lacquer, i-powder coating njl.

Ukubonakala, ukuxhathisa ukubola kunye neempawu zoomatshini zentsimbi yeshidi kunokuphuculwa nge-anodising.I-Anodising idla ngokubandakanya amanyathelo enkqubo afana nokukha kunye nokucoca, i-electrolytic oxidation kunye nokutywinwa konyango.

Ukufakwa kwesinyithi seshiti yinkqubo eqhelekileyo yonyango yomphezulu ukunyusa ukuxhathisa kwe-corrosion, i-aesthetics kunye ne-conductivity yombane ye-sheet metal ngokuyigquma ngentsimbi encinci okanye i-alloy.

Siyifektri yesiko lobuchwephesha, esinokuhlangabezana neemfuno zobukhulu obahlukeneyo, izixhobo kunye nonyango lwangaphezulu.Sizibophelele ekudaleni imeko yokuphumelela.Ukuba uneeprojekthi okanye izimvo, nceda ukhululeke ukunxibelelana nathi.Unokusithemba ukuvelisa iimveliso.Iqela lakho lingagxila ekuthengiseni kwaye lifezekise ukusebenza kakuhle.